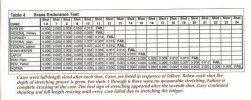

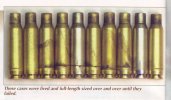

There are two kinds of common brass failure. In my experience of loading many different calibers for over fifty years, a split on the neck of the cartridge is most common. This can be addressed with annealing. How often to anneal is debatable, and you'll note from the chart provided by Brickburn that the quality of brass varies widely. Annealing after every 4-5 firings will probably work for most. Ultimately the brass itself will tell you. A neck split is not dangerous, but the brass is ruined because you cannot get neck tension on the bullet, required for proper combustion of the powder. The other kind of split is what Brickburn showed in his photos which is head separation. This is caused then the brass is full-length resized which causes the shoulder on the brass to be moved back a little bit (thousands of an inch) but each time it is fired the brass stretches to fully form in the chamber. The place it stretches is at the back of the case, hence the shiny ring. An improperly adjusted full-length sizing die will exacerbate this problem by moving the shoulder back too much. If you see this IMMEDIATELY DISCARD that case as the brass can catastrophically fail and completely shear there. Most modern guns have good gas escape systems so probably no damage to you (always wear protective glasses) but when you eject the round you'll pull out just the sheared head and now most of the case is stuck in the chamber squeezed in by thousands of PSI of pressure. They are difficult to get out and you may have to go to a gunsmith to get it out. More importantly, you said you want to reload .470 NE. You ain't shootin' bunny rabbits! You sure as hell do not want a broken shell stuck in your chamber when hunting DG. Your actual hunting ammo should be new or once-fired brass - don't risk it. There is a good solution to this stretching problem and that is not to full-length resize every time. Assuming you are shooting only one .470 NE, your brass will fire-form to the chambers. You can just neck-size the brass and it will last much longer and likely gain a little accuracy. Assuming again you have a double rifle, each chamber is unique, so you would have to keep the brass separate for each chamber, although you can experiment and see if the chambers are close enough to be interchangeable. You will know if the finished round drops in and closes without a problem. You still have to watch your overall case length as some stretching will still occur, but a LOT less. Trim as necessary and full-length resize when they won't drop in as they should. PS: full-length resizing will also make your cases grow in length faster so you have to trim more. Hopefully, I haven't scared you away from starting to reload. I virtually never buy loaded ammo unless that is the only or cheapest way to obtain brass. You will get to pick whatever bullet you want and tune the load to your specific rifle. You can tune the point of impact on your double by adjusting the powder load, so may get an accuracy bonus as well. All that said, there is a substantial investment in reloading equipment to take on the .470 NE. You'll need a press big enough to handle NE cartridge length, dies, scale, powder measure, a trim machine or trim die, loading blocks, etc. It will add up but your payback will be fast at $10 - $15 a round for purchased ammo. The bottom line will be how much you practice with your 470 NE and whether you consider crafting your own ammunition enjoyable. If you just shoot a couple of boxes before a hunt it won't payout. I shoot hundreds of rounds in practice before any safari so I get a huge savings. Good luck!