You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mannlicher Schönauer 'Prewar' M1900, M1903, M1905, M1908, M1910, M1924, 'M1925' or 'High Velocity'

- Thread starter Brian Rothhammer

- Start date

Brian Rothhammer

AH fanatic

Proof marks from my rifle!

/Andreas]

Yours is not the typical Mannlicher Schoenauer.

First, as there is no photo showing what may remain of the roll stamp on your receiver ring (where the claw mount dovetail cuts through it), what makes you convinced it is (was) an M1910? Also, how are you sure that it is chambered for 6.5X55?

Unaltered M1910 markings, 1924 through 1938. 'Made in Austria' having been added in 1924, changed to 'Made in Germany' in 1938.

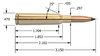

The early models of MS sporting arms were cartridge specific, each MS proprietary cartridge corresponding to the model of MS for which it was chambered. All M1903 were 6.5X54, M1905 - 9X56, 1908 - 8X56, M1910 - 9.5X57 known as .375 Nitro Express Rimless to the British trade.

Note, "6.5X53 and 6.7X53 are one and the same cartridge" It is the same that is now commonly referred to as 6.5X54. Catalogs of the day often used different reference points for measurement of cartridges and bores.

The Schoenauer magazine rotor was machined to cradle cartridges of a specific profile as were the walls of the receiver wherein the magazine resides which creates difficulty in performing cartridge conversions on the early MS.

M1903 (6.5X54) Schoenauer magazine.

Note how differently shaped 6,5X54 cartridges are from the M1910's 9,5X57 (DWM 531) in the image above.

With that said, your barrel clearly appears to be a replacement.

On to your proofs.

Here are the types of proofs typically found on Mannlicher Schoenauer rifles and stutzen (full stocked carbine) proofed prior to the Anschluss (annexation of Austria by Germany, March 1938 through WW2):

On this example, NPv on the receiver is the smokeless powder ('nitro') proof of Vienna. On the barrel, 4143 (also visible on underside of receiver, fore of barrel lug) is the Steyr serial number, 3001 is a proof house registry number, 411.08 on barrel and on receiver indicates that this was the 411th arm so proofed in the year 1908, C6.5 indicates 'caliber' (M1903 - 6.5X54), and visible on underside of barrel is the script EV of the Vienna Proof House.

On the underside of receiver is the mark, -15. Somewhere (not visible in photo) on the barrel would be a corresponding +15. These were to match proper chamber depth of barrel to receiver.

Now yours:

On the receiver are the expected Austrian proof marks indicating Steyr serial number 7706, followed by 1365.24 which indicates the 1365th arm 'nitro proofed' at Vienna in 1924. Also visible the NPv mark for that proof, and a -15 behind the barrel lug.

Your barrel markings are entirely different.

Visible in the images above is the C6.7 stamp for 'caliber' (remember the note under DWM cartridge image), below which we find the script EV of the proof house at Vienna, a number 236.5 (?) and a 36. Absent is a Steyr serial number and a +15 to offset the -15 on your receiver.

Here's where it gets interesting.

Remember I mentioned Anschluss? Your barrel also bears these proofs, which I knew looked familiar and sent me digging through old posts from a very knowledgeable gentleman (Axel Eichendorff) known as Kuduae.

'Normally' I would read the 36. stamp on your barrel as a German proof date of 1936, even with the script EV of the Vienna proof house and NPv for Austrian Nitro proof. I have no idea what the K and 6 indicate.

Austrian proofs do frequently coincide with Anschluss proofs. That particular double headed gooney bird, however, was only used during the early years of Anschluss; specifically 1938 - 1940.

Per Kuduae:

This eagle for primary proof was used only for a short time, from 1938 to 1940. After the "Anschluss" it replaced the single headed eagle with hammer and sickle in the claws, the symbol of the 1918 - 1938 Austrian republic. From 1940 to 45 the Vienna, Ferlach and Weipert proofhouses used the then new German proofmarks.

The thread is well worth a read: http://forums.**NOT**PERMITTED**.com/printthread.php?Cat=0&Board=mannlicher&main=314644&type=thread

Also, from another thread:

The combination of "Made in Germany" and Austrian NPv or NPf proofmarks is not unusual. In fact this alone dates a gun to 1938 – 39. After Austria was annected (with much applause by many Austrians, a fact now forgotten by them) by the 3rd Reich on March 12, 1938, not everything changed immediately. A new German proof law was already worked on. So the former Austrian proofhouses, Vienna and Ferlach, continued to use their procedures and stamps until the new, 1939 law, proof rules became valid on April 1, 1940. The .39 date was not applied by the Steyr factory, but by the proofhouse. Only from then on guns made in former Austria were marked with the German eagle/N proofmarks and the German month+year dates. So your rifle was not sitting in stock, already proofed, since the 1920s, but was assembled and proofed in 1939.

The thread: http://forums.**NOT**PERMITTED**.com/showflat.php?Cat=05826500&Number=289372&page=5&fpart=2&vc=1

There's something 'screwy' about this. Why would your barrel bear an Anschluss proof date of 1936 when the takeover of Austria did not happen until March of 1938?

Mysteries abound.

Your British proof marks appear to be from a later date. I'm not anybody's expert regarding British proofs, but from what I've found it seems that to rate firearm pressure capacity in tons was a practice that began about 1954:

Here we see several British proof marks from the chart above. On the receiver is a London 'definitive proof', on receiver can be seen the 'sword arm above NP' for smokeless (Nitro) proof, 6.5M/M, 2.11 may be a powder load (?), and the rating of 17.5 TONS, which the chart above indicates as 1954 or later. Is there an LP or LPH stamped anywhere on your barrel followed by a two digit number?

Also, what is stamped on top of your barrel? One can barely make out the last 'IA' of Made in Austria on your receiver ring, but could you provide more photos showing every mark and stamp on the MS?

Mysteries are fun, and we'll get to the bottom of this one!

Enjoy!

Attachments

-

38410946um.jpg92.6 KB · Views: 141

38410946um.jpg92.6 KB · Views: 141 -

38410932fg.jpg79.6 KB · Views: 132

38410932fg.jpg79.6 KB · Views: 132 -

38410935lh.jpg78.8 KB · Views: 138

38410935lh.jpg78.8 KB · Views: 138 -

38410940hb.jpg87.4 KB · Views: 127

38410940hb.jpg87.4 KB · Views: 127 -

38410943hd.jpg85.1 KB · Views: 126

38410943hd.jpg85.1 KB · Views: 126 -

38410933dm.jpg97.5 KB · Views: 130

38410933dm.jpg97.5 KB · Views: 130 -

38410948wt.jpeg91.1 KB · Views: 132

38410948wt.jpeg91.1 KB · Views: 132 -

38410924dz.jpeg58.2 KB · Views: 123

38410924dz.jpeg58.2 KB · Views: 123 -

38410921lh.jpeg42.3 KB · Views: 125

38410921lh.jpeg42.3 KB · Views: 125 -

38411015ql.jpeg10.4 KB · Views: 129

38411015ql.jpeg10.4 KB · Views: 129 -

38410967wg.jpg22 KB · Views: 118

38410967wg.jpg22 KB · Views: 118 -

38410970xt.jpg323.2 KB · Views: 132

38410970xt.jpg323.2 KB · Views: 132 -

38410972ss.jpg176.4 KB · Views: 130

38410972ss.jpg176.4 KB · Views: 130 -

38410959ih.jpeg68.4 KB · Views: 121

38410959ih.jpeg68.4 KB · Views: 121 -

38411045yk.png236.2 KB · Views: 127

38411045yk.png236.2 KB · Views: 127

Last edited by a moderator:

Shootist43

AH ambassador

- Joined

- Apr 25, 2015

- Messages

- 7,232

- Reaction score

- 9,003

- Location

- Grosse Ile, Michigan

- Media

- 28

- Member of

- NRA

- Hunted

- Michigan, Texas, Missouri, Limpopo Province South Africa

I'm way out of my league on this one but after doing a little research the 17.5 Ton proof converts to 38,526 PSI. That isn't a heck of a lot. What am I missing? Please educate me!! That is slightly more than HALF the pressure the 6.5 x 55 Swedish Mausers were "Proofed" at, i.e. 65,000. And yes I know that the 65,000 PSI is a conversion of the CUP actually employed.

Brian Rothhammer

AH fanatic

I'm way out of my league on this one but after doing a little research the 17.5 Ton proof converts to 38,526 PSI. That isn't a heck of a lot. What am I missing? Please educate me!! That is slightly more than HALF the pressure the 6.5 x 55 Swedish Mausers were "Proofed" at, i.e. 65,000. And yes I know that the 65,000 PSI is a conversion of the CUP actually employed.

I was thinking the same, myself, but what do I know? I'm just an American and those blokes speak English, a rather peculiar language.

Then I found this on another forum:

Excerpts:

This sort of confusion is what happens when you apply common sense and logic to British measurements.

I found this quote several times while searching for "British proof":

"Per the 1954 Rules of Proof, here are the equivalent service pressure values:

3 tons--8,938 psi "

Don't ask me how that works.

Anyway, 6 times 8,938 psi = 53,628 psi = 18 "tons" per square inch, about right for a 30-06.

-----------------------------------------------------------------------------------------------------------------------

The problem appears to be that way back when they used a Lead Crusher Radial system to proof firearms. When they began changing over to a newer system they had to settle on a number to use in the conversion formula because they couldn't figure how the old system complared to the new one. I'll quote a guy who appears to know a lot about it.

http://kwk.us/pressures.html

"No accurate conversion between crusher and true pressure exists, but approximations can be made"

---------------------------------------------------------------------------------------------------------------------------

Pre-metrication British chamber pressures are:

1. Based on the long ton of 2240 lbs,

2, Measured with an axial crusher gauge with element in a modified bolt head, not a radial gauge with hole in barrel.

These combine for lower numerical readings than US radial crusher gun CUP and lots lower than piezo psi.

It does not mean that the rifle has not been thoroughly tested and it is not unsafe with fresh ammo.

Your gun is fine.

-------------------------------------------------------------------------------------------------------------------------------

Gough Thomas correlated British and Yank pressure ratings and concluded that a long ton of load on a axial crusher was equivalent to about 2800 lbs dead load on a US type radial crusher gauge.

----------------------------------------------------------------------------------------------------------------------------------

The 'meat and potatoes':

Cartridge Pressure Standards

In the U.S., voluntary pressure standards for rifle cartridges are set by SAAMI, a member of ANSI. Most other countries in the world follow the standards of Europe's CIP (Commission Internationale Permanente pour l'Epreuve des Armes à Feu Portatives or Permanent International Commission for the Proof of Small-arms, sometimes referred to as the International Proof Commission).

Conversion Formulas

No accurate conversion between crusher and true pressure exists, but approximations can be made. In all the conversions here, pressures are in ksi. Expect errors of several ksi, or about 15%, with such formulas. Many factors determine how much the indicated pressure reading from a crusher misses the true pressure, and the error varies among cartridges and even among different loads for one cartridge. The following conversions might be accurate enough for many practical purposes.

In Denton Bramwell's article, he offers a formula he derived using a basic statistical analysis of SAAMI's ratings, covering only pressures between 28,000 and 54,000 CUP :

piezo = 1.52 * crusher - 18

He also demonstrates that within this pressure range, the CIP appears to have generally used a simple conversion between their crusher and piezo ratings, roughly equal to:

piezo = 1.21 * crusher - 2.8

CIP pressures are multiples of 50 bar (about 700 psi), probably rounded after the conversion. (Please note that CIP crusher readings should not be equated with SAAMI CUP crusher readings; see below.)

In the 09/1968 issue of Handloader, Lloyd Brownell presents test data (crusher, but not necessarily CUP) which suggests to me a linear conversion formula is not the best choice, and in my Powley Computer I use:

piezo = crusher * ( 1 + ( crusher^2.2 )/30000 )

From 0 to about 60 ksi crusher, it fits both SAAMI's ratings and Brownell's data well, but it is low at the high end of Brownell's data. Brownell's data shows little to no error below 20 ksi, and a curve fit to only his data between 20 and 67 ksi crusher is:

piezo = crusher + ( (crusher - 20) ^ 2.3 ) / 210

Reference Ammunition

Under SAAMI specifications, reference ammunition is required only for the qualification of new pressure barrels. A new pressure barrel must demonstrate it generates nearly the same pressure and velocity as existing SAAMI spec. pressure barrels. Reference ammunition is as uniform as possible, and ideally all pressure barrels will show the same indicated pressure and velocity. If one barrel is found to be different, something is off in either the barrel or its sensors.

Reference ammunition is not used to calibrate pressure sensors. Piezo systems are calibrated hydraulically. Crushers are calibrated by the manufacturer. (The use of reference ammunition to try to correct crusher measurements is listed as "optional.") To quote SAAMI: "Reference Ammunition cannot guarantee the absolute accuracy of any test system."

CIP procedures permit the use of reference ammunition to correct pressure readings taken at any one lab. The reference ammo has been fired at several trusted labs, and the average of these readings is the reference value. Reference cartridge pressures measured at any other lab are compared to the reference value, and if the difference is less than 10%, the offset can be used as the correction in subsequent tests at that lab.

Proof Loads

For rifles, SAAMI recommends a proof load between 33 and 44 percent over the nominal rating, and the CIP today requires 25 percent over their rating (an older standard called for 30% over). While SAAMI requires only a single proof firing, the CIP wants two firings, except in long guns designed for low pressure cartridges (under 26 ksi), where only a single proof cartridge need be fired.

For handguns, the CIP uses 30 percent over, while SAAMI varies the proof load with the rated pressure. For cartridges rated over 20 ksi, SAAMI uses the same overloads as with rifles, but low pressure cartridges have a higher overload, with those rated under 15 ksi having a minimum of 44% over.

To conduct a proper proof, one would ideally need precise gauges to verify no stressed part has yielded (ie., taken a permanent deformation) in the slightest. If no yielding occurs at the proof pressure, then the gun should have an adequate fatigue life at normal operating pressures. I've read that in practice, visual inspections are permitted on production guns, so I suspect properly instrumented proofs are only conducted on prototypes.

Interestingly, the same percentage overload is used with both piezo and crusher ratings at SAAMI. Above, it was noted there is evidence that crusher's underestimation of pressure grows ever worse as the true pressure rises. One curious side effect is that rifles proofed with crushers may well be proofed to a higher standard than those proofed with piezo.

Under the British base crusher standards described below, proof loads ran 30 to 45% above normal. To maximize breech thrust, proof cartridges were oiled before firing.Kynamco in England still rates their production cartridges with this method.

Piezo systems have been available since the 1920s and today are the accepted standard, but other systems to produce a pressure trace were tried. Vieille in France, who developed the first military smokeless powder, also "invented a rotating recording crusher gauge with which pressure could be measured as it varies with the time." I have no details on Vieille's crusher, but I've read he was the first to detect pressure waves inside the chamber. The Russian researcher Serebriakov employed in 1923 "a conical crusher" to investigate burn rates in a calorimeter—again, no further details. In the U.K., J. J. Thomson began experimenting with piezo systems during WW-I. A system demonstrated to the Springfield Armory in 1921 had the chamber piston press against "a very stout stiff steel bar, which had a polished end forming a reflecting surface to act as a mirror." A light beam was reflected onto a revolving drum of film to record the pressure trace.

Piezo systems measure the displacement of electric charge in a crystal as it is compressed. For SAAMI tests, a piston in the side of the chamber is cut to conform to the case. This leaves the brass cartridge case between the gas and the sensor, but the sensor is calibrated by hydraulically pressurizing a test chamber with a case in it, and in this way the effect of the case is known.

It is possible to measure the pressure more directly, without the conformal piston. Older VihtaVouri test data (2nd ed.) was taken with the piezo sensor just in front of the case mouth, and NATO does this as well. However, the pressure is slightly lower there, and one cannot sense the pressure until the bullet's base has passed, preventing one from seeing how smooth is the initial ignition of the charge. One can also cut a small hole in the case to align with a narrow pressure sensor port, and the CIP uses this method. Either way can expose the sensor to the hot gases, leading to shorter sensor life. However, neither a conformal piston nor calibration of the brass case is required, and these approaches will likely be less expensive than SAAMI's.

Other pressure transducers can be used in place of the piezo transducer. Once more common was one using a strain gauge. Such transducers fit where the piezo unit does in modern tests.

Strain gauges can also be used in an another fashion to measure pressure. The strain gauge is glued to the surface of the barrel, over the chamber, and the "hoop" strain is measured from the small changes in resistance in the gauge's wires. The test barrel ideally has somewhat thinner walls, allowing for greater strain during firing. One must also compute an offset to compensate for the pressure being contained by the brass of the case. In a lab, this might be done hydraulically, as with piezo, but I've read it is not. The properties of cartridge brass are fairly well known, and the measurement of the brass thickness is readily done, so it's possible to compute the offset with fair accuracy. Strain gauge systems can be quite affordable; the Pressure Trace available from RSI is marketed to the handloader. Oehler Research also sells such systems for laboratory use.

Measuring Pressures in Handloads

In the U.S., H.P.White tests ammunition, and may be able to do so for home handloads. In recent years, Western Powders advertised a modestly priced service to test handloads in their piezo rigs, but as of late 2006 that service is not listed on their web site. In Europe, the Birmingham Proof House in the U.K. will test handloads as will DEVA in Germany, and other national labs might as well.

-------------------------------------------------------------------------------------------------------------

There it is, as clear as mud!

Last edited by a moderator:

Brian Rothhammer

AH fanatic

I’ve got an idea of the proof mark. 2.11” . 2.11 inches is about 2.11x25,4= 53,594 mm. So my conclusion is that this barrell orginal was chambered for 6,5x54 M-S.

//Andreas

I'm thinking not.

The rotor in his magazine appears to be from an M1903 (or Y1903) that has been modified, lending credence to the 6.5X55 notion.

Attachments

Last edited by a moderator:

Brian Rothhammer

AH fanatic

New pictures!

Thank you for providing more images.

Let's start with stamps that Steyr applied when your M1910 was manufactured:

This is the Steyr serial number of your Mannlicher Schoenauer, as stamped on the receiver. The original barrel would also have had this stamp. There should be a number on the underside of your bolt handle (as in the image below). If original to your MS, it will be 7706.

This stamp on your extractor is also present on my original 1922 proofed M1910, as are the circle with enclosed cross on the bolt head and on the nut.

Now on to stamps not placed by Steyr:

These are British proofs, the crown V of a London 'view' and crown CP of the London second proof.

My M1910 has the crown BV, or Birmingham view mark, in the same location.

This two digit numerical (73) stamp is not present on the magazine rotor of my MS, nor is anything like it. I suspect it was some sort of military mark from a 'Greek contract' Y1903 or perhaps placed there by the craftsman that modified the rotor, but those are sheer guesses on my part. To the left and in partial shadow are what appear to be two vertical lines. Hard to tell by the photo but are these seams from the rotor having been cut and rewelded?

This is not the magazine rotor of an M1910. It is likely the 6.5X54 rotor from either an M1903, or the far more widely available Y1903 'Greek', that has apparently been reconfigured. If I'm 'reading' this image correctly there appears to be a 'saddle' expertly welded and fitted where the cartridge neck would rest, a critical area of alignment to keep cartridges feeding smoothly through the Schoenauer magazine.

This image shows M1903 magazine (6.5X54) at left, M1910 (9.5X57) right.

Now for the interesting bit.

With this image it is now quite plain to me where you 'got the idea' that your MS was originally an M1910

.

.

What I find to be rather interesting is the 'Made in Austria' stamping on your barrel.

Over the decades, particularly in more recent years of internet searches, I have seen images of hundreds of pre WW2 Mannlicher Schoenaurs and I am almost certain that I have never seen that stamping (or anything like it) on the barrel of an MS.

The 'Made in Austria' stamp on your receiver was used from sometime in 1924 onward (changed to Made in Germany during the 1938 -45 Anschluss years) and is consistent with the 1924 Austrian proof date stamped on your receiver as is this stamping on your left receiver rail. The company name changed to Steyr - Werke AG in 1926.

'Curiouser and curiouser'

Back to your 'Made in Austria' stamp on the barrel, it certainly appears to have been very neatly and deeply stamped into the barrel prior to installation which makes me wonder if perhaps Steyr marked replacement barrels in that manner between 1924 and 1938?

Again, I'm thinking I have never seen such a stamping previously. It is, however, somewhat reminiscent of the stamp applied by Steyr to the M1924 'Sequoia' models which were so marked for import to the U.S. to be sold by the Sequoia Importing Company.

So here's where I am with your MS information thus far:

Your MS was originally manufactured as an M1910 (9.5X57) with the factory take down system. It received proofs at Vienna in 1924 that are very consistent with other MS rifles and stutzen of the period.

Sometime afterward its magazine rotor was replaced with an altered 6.5X54 rotor, apparently quite well and by an expert craftsman, and received a barrel change. This may have occurred in 1936 but that is profoundly inconsistent with the 'Anschluss only' double headed eagle stamp, used only from 1938 through 1940, that appears on your barrel. That mystifies me.

Eagle of type used only from 1938 - 1940.

Was it changed out in '36 and then reproofed for some reason later? If so one would expect to see a later date stamp in the form of a two digit number followed by a period.

If the '36.' stamp is an error, with the six being an inverted '9' stamp, that would explain things nicely. Problem is, that '39.' stamp has the appearance of being a single stamp rather than a '3', a '9', and a '.' stamped individually.

Could you provide a clearer image of the 'Anschluss eagle' stamp? Is there a number or letter on the eagle's breast?

The British proofs, from data posted above, seem to have been applied sometime between 1954 and 1989. I suspect they have nothing to do with the conversion or rebarrel except that, from what I've read, British proof houses did not accept Anschluss proofs so that would require a reproof when brought into Britain.

I'll float these questions by the folks at **NOT**PERMITTED** and see if anyone bites. Herr Eichendorf (Kuduae) is a member both there and here so perhaps he'll weigh in. He has a far greater depth of knowledge on these matters than do I.

Enjoy!

Attachments

-

38417830vt.jpeg93.7 KB · Views: 119

38417830vt.jpeg93.7 KB · Views: 119 -

38418042ee.jpg5.1 KB · Views: 118

38418042ee.jpg5.1 KB · Views: 118 -

38417833zr.jpeg40.1 KB · Views: 115

38417833zr.jpeg40.1 KB · Views: 115 -

38417834oq.jpeg66.8 KB · Views: 113

38417834oq.jpeg66.8 KB · Views: 113 -

38417845ox.jpeg82.6 KB · Views: 107

38417845ox.jpeg82.6 KB · Views: 107 -

38417862dw.jpeg184.4 KB · Views: 111

38417862dw.jpeg184.4 KB · Views: 111 -

38417863kf.jpeg55.6 KB · Views: 114

38417863kf.jpeg55.6 KB · Views: 114 -

38417991ec.jpg25 KB · Views: 114

38417991ec.jpg25 KB · Views: 114 -

38417994rz.jpeg319 KB · Views: 114

38417994rz.jpeg319 KB · Views: 114 -

38418217ty.jpeg18.2 KB · Views: 120

38418217ty.jpeg18.2 KB · Views: 120 -

38417997du.jpg32.6 KB · Views: 100

38417997du.jpg32.6 KB · Views: 100 -

38418134uj.jpg20.3 KB · Views: 122

38418134uj.jpg20.3 KB · Views: 122 -

38418185wo.jpeg42.3 KB · Views: 113

38418185wo.jpeg42.3 KB · Views: 113

Last edited by a moderator:

Shootist43

AH ambassador

- Joined

- Apr 25, 2015

- Messages

- 7,232

- Reaction score

- 9,003

- Location

- Grosse Ile, Michigan

- Media

- 28

- Member of

- NRA

- Hunted

- Michigan, Texas, Missouri, Limpopo Province South Africa

Brian Rothhmmer, I am enjoying your contributions to this thread immensely. Your dogged pursuit of an answer is to be commended. IMHO the OP owes you a virtual beer, as well as his heartfelt thanks.

Brian Rothhammer

AH fanatic

Brian Rothhmmer, I am enjoying your contributions to this thread immensely. Your dogged pursuit of an answer is to be commended. IMHO the OP owes you a virtual beer, as well as his heartfelt thanks.

Attachments

Brian Rothhammer

AH fanatic

I’ve got an idea of the proof mark. 2.11” . 2.11 inches is about 2.11x25,4= 53,594 mm. So my conclusion is that this barrell orginal was chambered for 6,5x54 M-S.

//Andreas

I'm thinking not.

The rotor in his magazine appears to be from an M1903 (or Y1903) that has been modified, lending credence to the 6.5X55 notion.

I now agree with your assessment and apologize for having doubted you.

Being unfamiliar with the 1954 - 1989 British proof system, I had to compare images of other firearms Brit proofed during that period to compare.

My M1910 bears British proofs from the 1920s along with "9.5 M/M EX and Cordite 43 - 270 MAX ", which defines the 9.5mm projectile, a maximum load of 43 grains Cordite, and a 270 grain projectile - all quite useful information.

Apparently from 1954 through 1989 case length and 'long tons' per square inch of pressure as determined by a lead crush method was more important to British proof houses than bullet weight and powder charge.

Now, 54mm = 2.12598 inch, but take note of the 2.110" case length of 6.5X54 MS on the (quite British) Eley drawing below.

Attachments

Last edited:

Brian Rothhammer

AH fanatic

MS 9x56

AH elite

Brian since your main interest is in the older rifles I have a question regarding markings on my 1905 9x56 that was built in 1921. Do all Mannlicher Schoenauers imported to the U.S. bear import markings?All part of the fun!

Brian Rothhammer

AH fanatic

Brian since your main interest is in the older rifles I have a question regarding markings on my 1905 9x56 that was built in 1921. Do all Mannlicher Schoenauers imported to the U.S. bear import markings?

No, they do not. It is perfectly 'natural' and right proper for your 1921 proofed MS to lack the 'Made in Austria' stamp as that was not added until sometime in 1924. From sometime in 1938 (or whenever already stamped receivers were used up) through 1945 they were marked 'Made in Germany', then back to 'Made in Austria' throughout post WW2 production.

The above applies to all MS sporting rifles and stutzen, across all models, regardless of whether they were exported.

1900 - 1924 production.

1924 - 1938

Anschluss, 1938 - 1945

Attachments

Last edited:

Brian Rothhammer

AH fanatic

New pictures!

Here's my reply to HWL's answer my query regarding your MS (HWL in italics):

"First of all.... I have no idea....

...I only can speculate."

I appreciate your candor.

"Supposing that, it is possible, the replacement barrel was made in Austria in the year 1936...

...This does not mean, it was installed in 1936, but possibly later."

That is quite likely, and also what Kuduae (Axel Eichendorff) posits.

"Nontheless, I think the caliber of the gun is 6,5x54 Mannlicher-Schoenauer, not 6,5x55 Swedish...

...The Swedish would not fit into the magazine, an immense work to change it...

...And there are no proof marks indicating 6,5x55."

I'm thinking the M1910 (9.5X57) was rebarreled between 1938 - 1940 (the period in which that Anschluss eagle was used as final proof) with a barrel that had been 'provisionally proofed' in 1936. The problem with that theory is absence of a proof date after installation unless the K and 6 are some sort of date code. The London proof marks date from 1954 - 1989 and the 2.11", research shows, indicates case length which the (very British) Eley drawings of 6.5X54MS defines as 2.110 inches. Any rebore to 6'5X55 must have occurred after the British proof, so at least post 1953.

It seems that Ajez indicated 6.5X55 cycles through his action. If so, the chamber surely must have been widened to accommodate and the shoulder moved forward.

"I have never seen a barrel like this, stamped with "Made in Austria"."

Nor have I. That one's still a mystery.

------------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------------

Here is Kuduae's reply:

Nothing mysterious here, knowing the differences of Austrian vs. German gun-, prooflaws and -customs. Other than in Germany or USA in A. the barrel, not the receiver, was regarded as the essential part of a gun. Obviously this M1910 M-Sch was originally in 9.5x57 M-S. Later it was rebarreled to a 6.5 mm cartridge by another, not Steyr, maybe even later rechambered to 6.5x55 SE. It would be interesting to know the British proofmarks too. I have a M1900 M-S that was rechambered much later to 6.5x55SE and reproofed for that load by the Birmingham proofhouse in 1982. I did not find that rifle under the AH link you sent.

The C 6.7 caliber marking is Austrian , not German. Garmans marked the bore/land diameter, 6.5 = .256“, While Austrian proofhouses marked the groove diameter (called „bore diameter“ by Americans only) 6.7 mm = .264“. Remember, most European 6.5 mm cartridges are named for their land diameter and use 6.7mm bullets. That 36. Date is related to the provisional Vienna EV mark next to it. That denoted proof of an uncompleted barrel . So the spare barrel only was made in 1936 and marked then „Made in Austria“ in case it was to be exported. Two years later, 1938 -39 according to the shape of the eagle, it was fitted to the action and the assembly final proofed by the Vienna proofhouse. K6 maybe the Austrian „house number“ (code) for the maker of that aftermarket barrel.

Waidmannsheil

Axel

Last edited by a moderator:

Brian Rothhammer

AH fanatic

I send a heartly and big thank you to everyone educating me about those wonderful rifles!

And this virtual beer is actually german, but it’s send to you all from Sweden

Paulaner?

This is an advert from my Chilean cousin's cerveceria:

Attachments

Members online

- Stetsonham

- TXdawg

- aminkus

- gbflyer

- Tra3

- Wishfulthinker580

- YancyW

- Ndlawrence

- Lumaberpat

- 375Ruger416

- rtphotography

- Beretta391

- BGHNTR416

- TaylorM456

- Tex .416

- 375er

- Ozishooter

- WoodFire

- meigsbucks

- duckfish

- Ku-winda

- mark-hunter

- Elkbugling

- Houston Bill

- hornhunter!

- Dholupko

- lwaters

- jpr9954

- Bandera

- BoarHog375

- WISafariHunter

- John the Electrician

- Lee M

- Mully

- CM McKenzie

- Tanner Lee

- Lone Star Bluegrass

- Joedad

- Happy Myles

- Tubby’s Canteen

- mdwest

- Bearbait1

- Trail Rated

- TOBY458

- Connor Baumgarten

- Countrylife

- bwanamrm

- TEXLNGHRN

- 358 Norma

- SaintPanzer

Total: 51,887 (members: 1,242, guests: 50,645)

Forum statistics

Latest profile posts

Booked with Harold Grinde - Gana River - they sure kill some good ones - who'd you get set up with?

HI all, here is a Short update on our America trip, I currently in Houston and have 2 more meetings here before movings North toward Oklahoma, Missouri and Iowa, and from there I will head to Colorado and Idaho,I have been met with great hospitality and friendship, and have met several new and old clients and we are going to book the rest of 2025 season quick and have several dates booked for 2026!